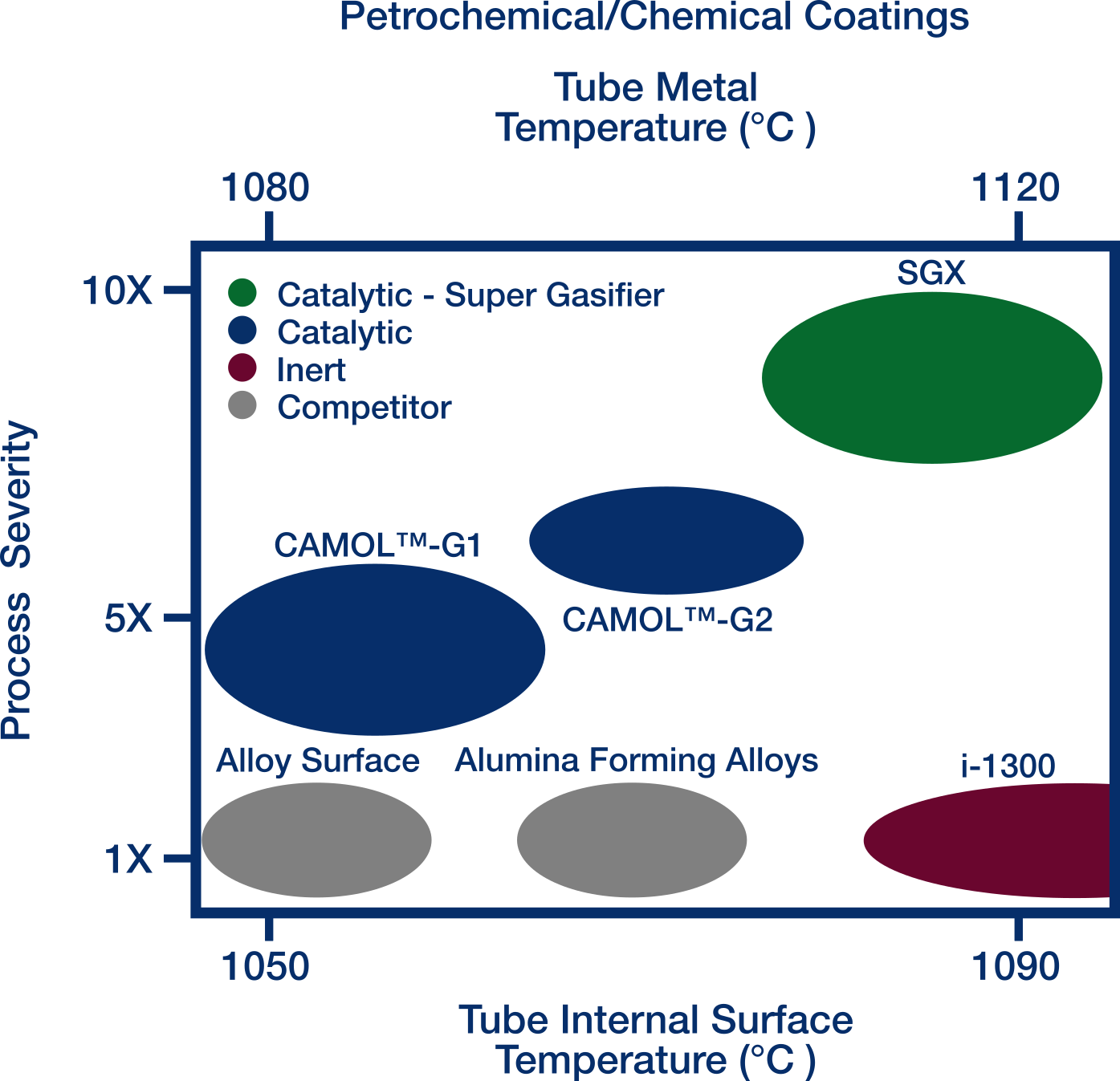

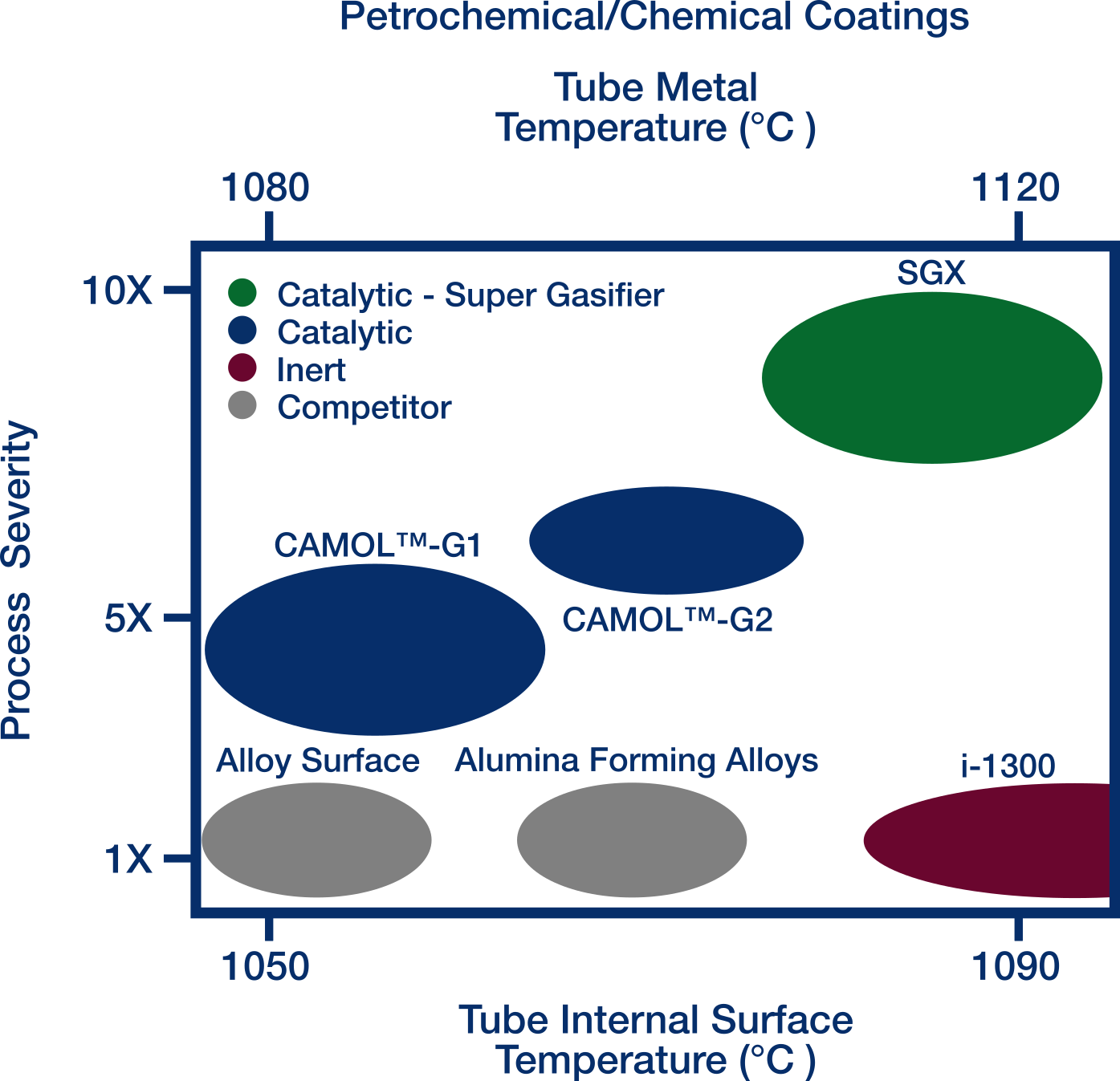

i-1300 HT and LT Inert Coatings for Ethylene Cracking and Delayed Cokers

- Highly inert to filamentous coke-make.

- Substantial energy and emissions reductions.

- Target high severity olefins production and refinery / upgrading operations.

i-1300 HT [Higher Severity]

- Inert-1300 High Temperature coating.

- World-first intrinsic inertness to filamentous coke-make.

- Highest coating thermal stability achieved in sector to-date.

i-1300 LTpc [Medium Severity]

- i-1300 Low Temperature Petrochemical coating.

- Low-cost alumina-forming coating for olefins production.

- Low oxide formation temperatures.

- Converts Fe and Ni from base steel into highly thermally-stable inert phases.

i-1300 LTdc

- i-1300 Low Temperature Delayed Coker coating.

- Inert to surface based coke-make mechanisms.

- Eliminates the formation of Fe-S-C coke layer.

- Eliminates any filamentous coke-make.

- Reduces feedstream “dropout” coke.

- Piggable to a broad range of carbide appendages.

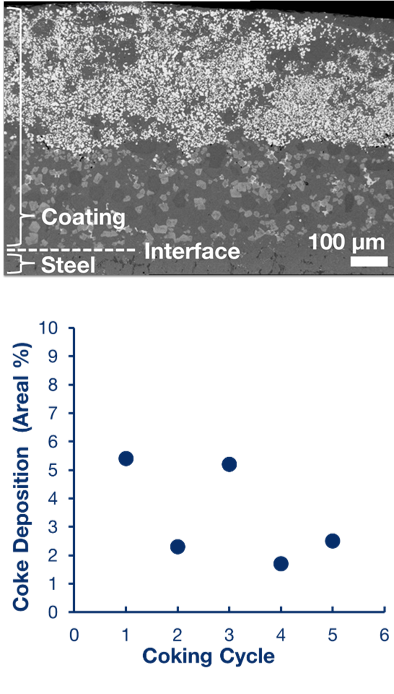

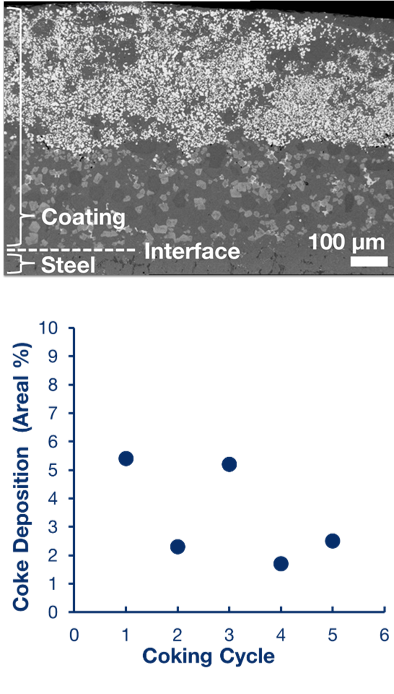

Engineered Properties

Surface and Coating Properties

- Inert to surface filamentous coke make.

- i-3000HT requires no surface oxide growth.

- i-1300LTpc grows alumina surface at lower temperatures.

- i-1300LTdc coating matrix is universally inert throughout entire coating matrix and piggable.

Degradation Resistance

- Oxidation

- Carburization

- Sulfidation

- Temperature Extremes/Upsets for (HT)

- Piggable (i-1300 LTdc)

Key Mechanical Properties

- CTE Matched

- Ductile and Weldable

Multiple Industry Applications

How It Works

i-1300 HT

World-first INTRINSIC inertness (>95%) to filamentous coke-make in higher severity olefins production in the hottest part of the furnace coil without the need for the prior formation of a surface oxide barrier.

i-1300 LTpc

Low-cost inert alumina scale former for use in the cooler parts of olefins production furnace coils without any weldability challenges.

i-1300 LTdc

Low-temperature INTRINSIC inertness to all surface coke-make mechanisms and reduction in feedstream “dropout” coke collection for use in Delayed Coker furnace coils. Intrinsic inertness requires no oxide growth and is piggable.

Targeted Field Performance

i-1300 HT & LTpc (Olefins Production)

- 8-10% reduction in energy and GHG emissions

- 1 year energy payback time

- Up to 3-5X longer runtimes in ethane

- Up to 2+X longer runtimes in naphtha

- 17kT CO2e/yr reduction per installation

i-1300 LTdc (Delayed Coker / Refinery)

- 4X decrease in pigging operations

- 1.5X increase in coil lifetime

- OPEX reduction via energy cost

- 8kt CO2e/yr reduction per installation