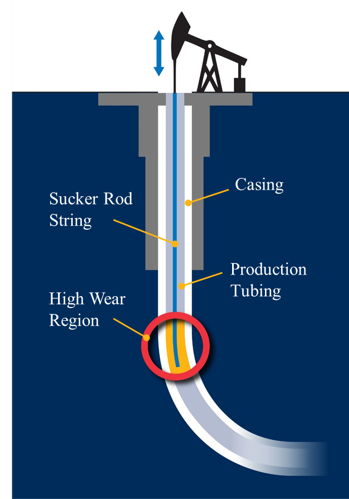

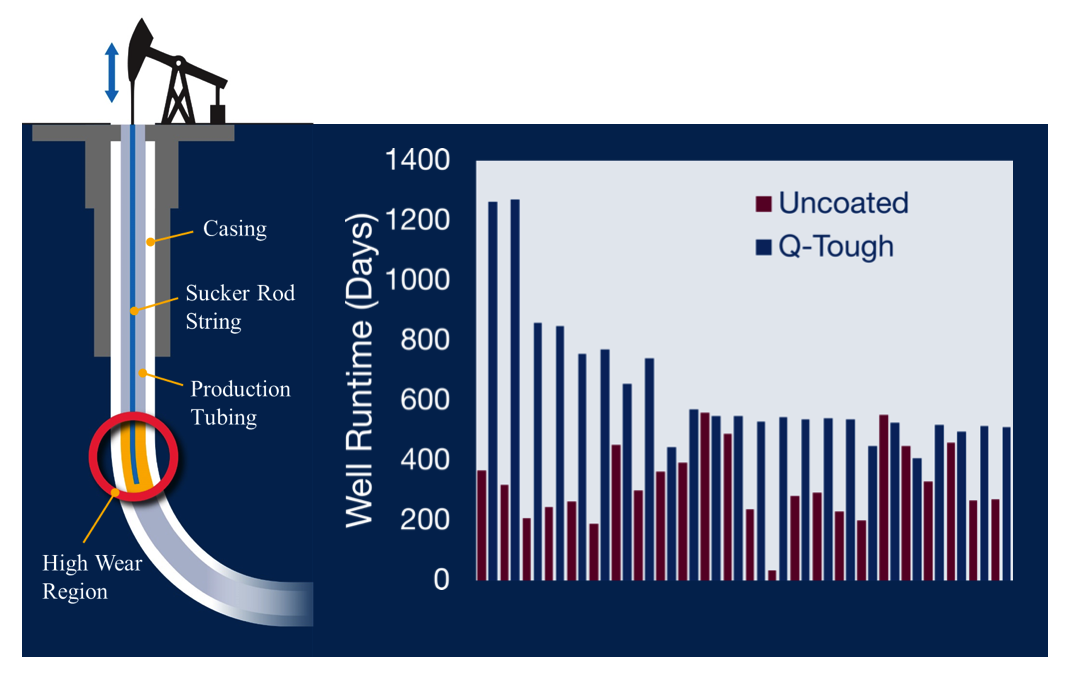

Production tubing lasts longer when Q-Tough is applied at high-wear locations, eliminating resource intensive workovers, reducing costs, and increasing reliability.

|

Property |

Details |

|

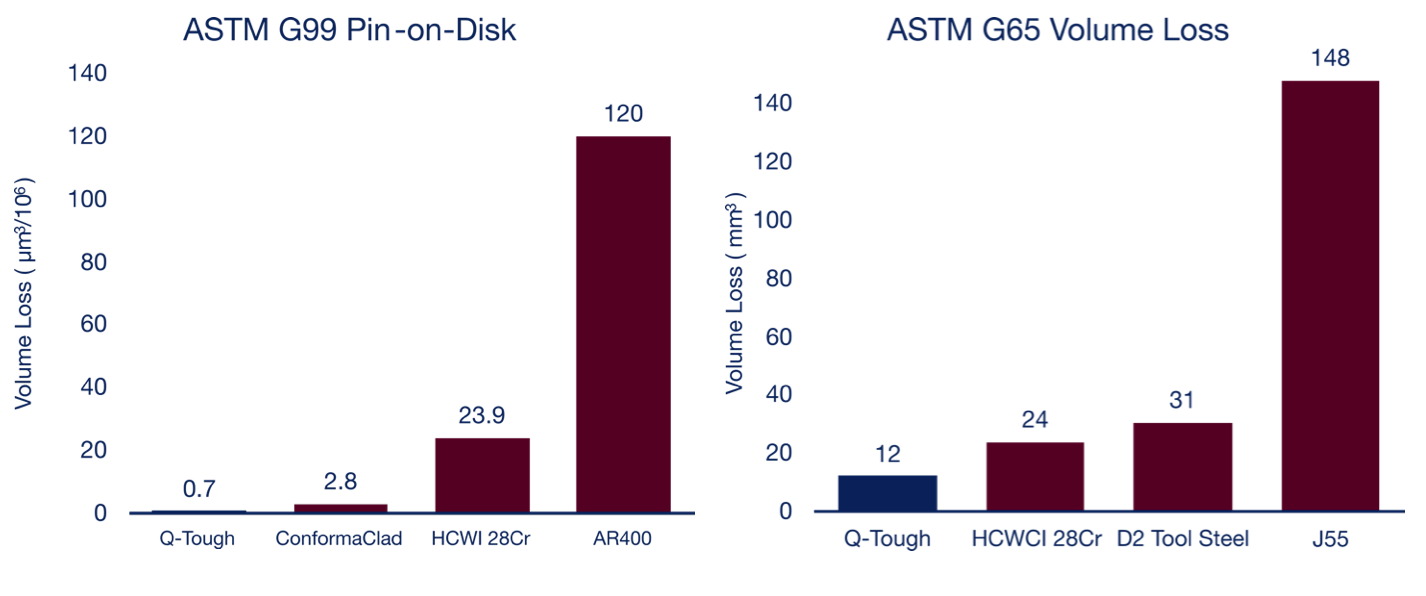

Sliding Wear Resistance (ASTM G99) |

>500X better compared to uncoated J55 carbon steel |

|

Sand Abrasion Wear Resistance (ASTM G65) |

>15X better compared to uncoated J55 carbon steel |

|

Slurry Jet Erosion Resistance |

Comparable to CrC overlays and white cast irons |

|

Substrate Compatibility |

Carbon and alloy steel, stainless steel, Ni-based alloys |

|

Part Sizes and Geometries |

Internal and External surfaces |

|

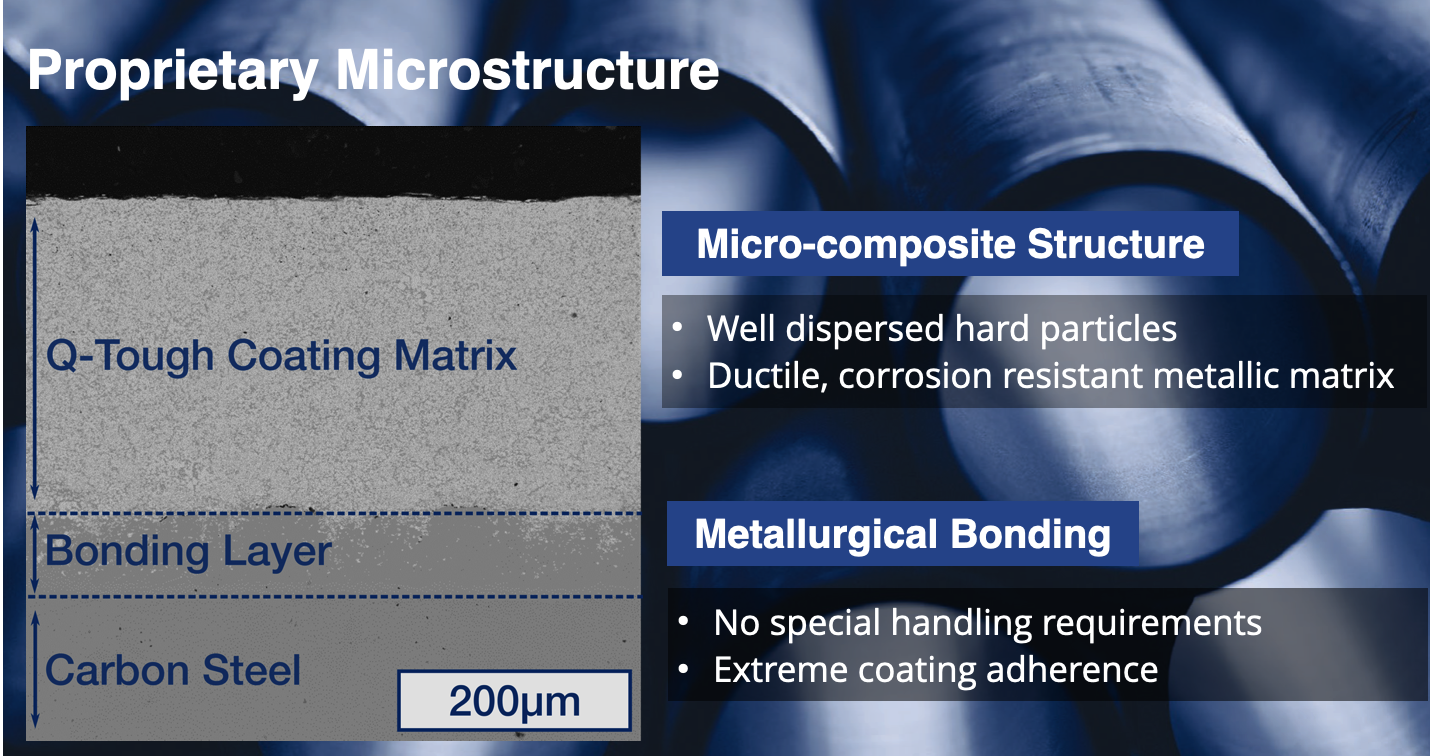

Average Microhardness |

~800 HV (63 HRC) |

|

Coating Thickness |

50 - 1000 µm (0.002" -0.040") |

|

Substrate-Coating Bond Strength |

Excellent due to Metallurgical Bond |

|

Coating Porosity |

Minimal |

|

Appearance |

Smooth as coated finish |

Field trials of Q-Tough coatings have been installed in 44 wells in the Bakken region of North Dakota.