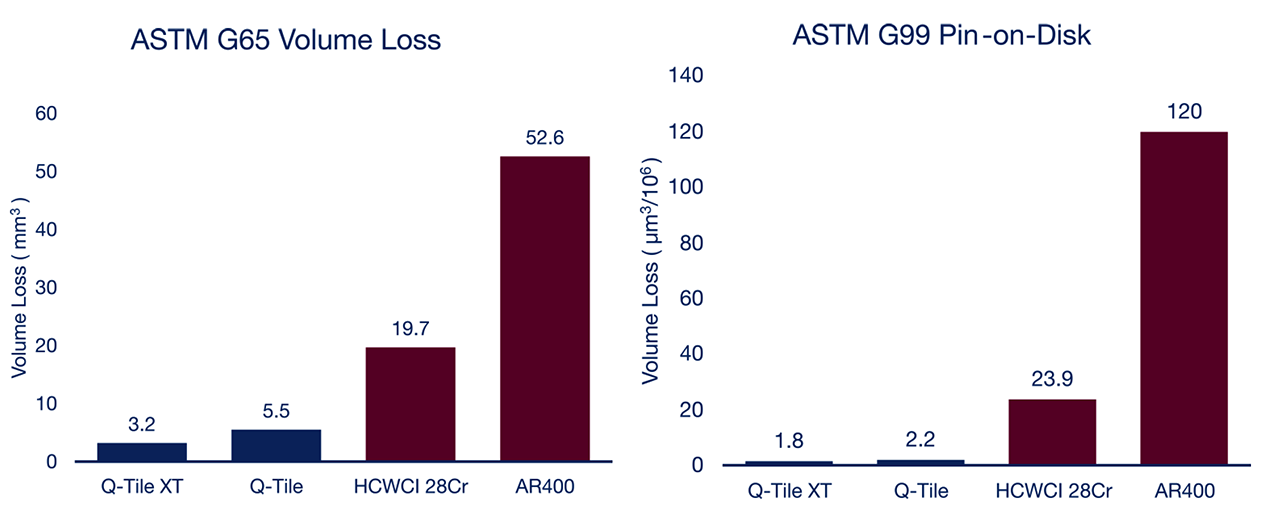

Q-Tile outperforms common industry standard wear resistance steels such as AR400 and High Chrome White Iron in a wide array of ASTM standardized testing.

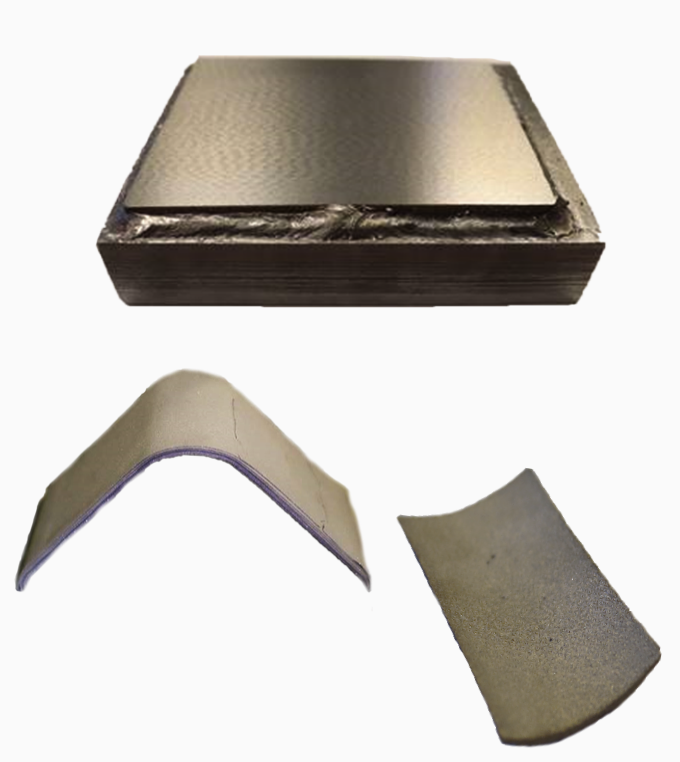

Q-Tile can be welded using the MIG technique. Recommend Stainless Steel, Incoloy alloy or preferably Carbon Steel rods. Q-Tiles can be brazed or vacuum sintered to any steel substrate using common B-Nickel aerospace brazes.

Currently, representing amongst the largest tiles commercially available, Quantiam’s tiles are currently available up to 6in (152mm) in width, 18in (457mm) in length, and 0.5in (12mm) in thickness. Larger sizes and thicknesses, and a variety of custom geometries are available.

|

Material Properties and Performance Testing |

HIGH Wear-resistant Tiles |

Reference Steels |

||||

|

Quantiam |

Quantiam |

Competitor |

HCWCI |

AR 400 |

||

|

Wear |

ASTM G65-A Volume Loss (mm3) |

5.5 |

3.2 |

3 |

19.7 |

266.6 |

|

ASTM G65-A Mass Loss (g) |

0.066 |

0.051 |

0.055 - 0.080 |

0.2 |

2.067 |

|

|

ASTM G99 Pin-on-Disk (x 106 µm3) |

2.2 |

1.8 |

23.9 |

120 |

||

|

NRC SJE Volume Loss (mm3) 90° |

1.8 |

0.6 |

14.4 |

75 |

||

|

NRC SJE Volume Loss (mm3) 45° |

2 |

0.7 |

12.8 |

126 |

||

|

Mechanical |

Rockwell Hardness (HRC) |

50 |

55 |

65 - 75 |

56 |

40 |

|

Vickers Hardness - Matrix (HV) |

649 |

575 |

- |

812 |

370 |

|

|

Vickers Hardness - Carbides (HV) |

1644 |

1429 |

1500 |

|||

|

ASTM G171 Scratch Hardness (GPa) |

8.9 |

9.4 |

9.1 |

3.4 |

||

|

ASTM B406 Transv. Rupture Strength (MPa) |

715 |

945 |

600 - 650 |

984 |

- |

|

|

Physical |

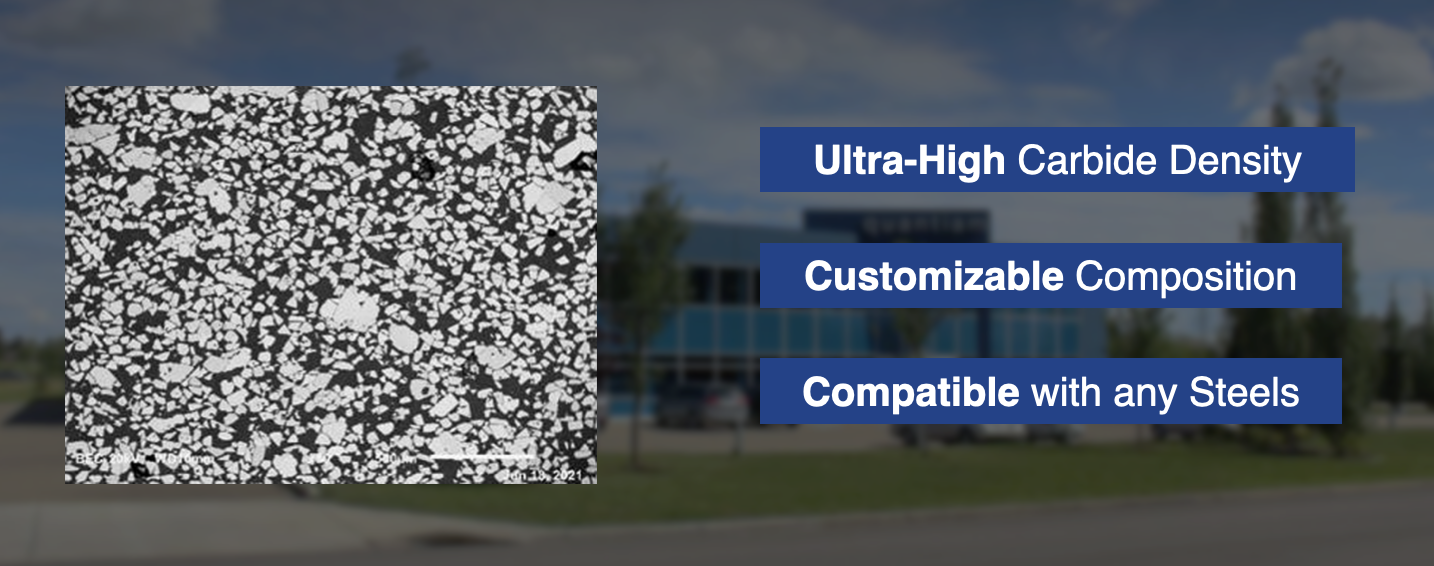

Carbide Area Fraction (%) |

37.3 |

52.7 |

|||

|

Carbide Sizes (µm) |

45 - 74 |

45 - 177 |

||||

|

Porosity (%) |

< 5 |

< 0.5 |

||||

|

Density (g/cm3) |

10.6 |

6.8 |

8 |

|||

Download our Q-Tiles (Wear Tiles) Brochure for more information

Download our Q-Tiles (Wear Tiles) Brochure for more information