The coatings improve operational efficiency and profitability, and reduce energy and emissions of steam cracker furnaces by:

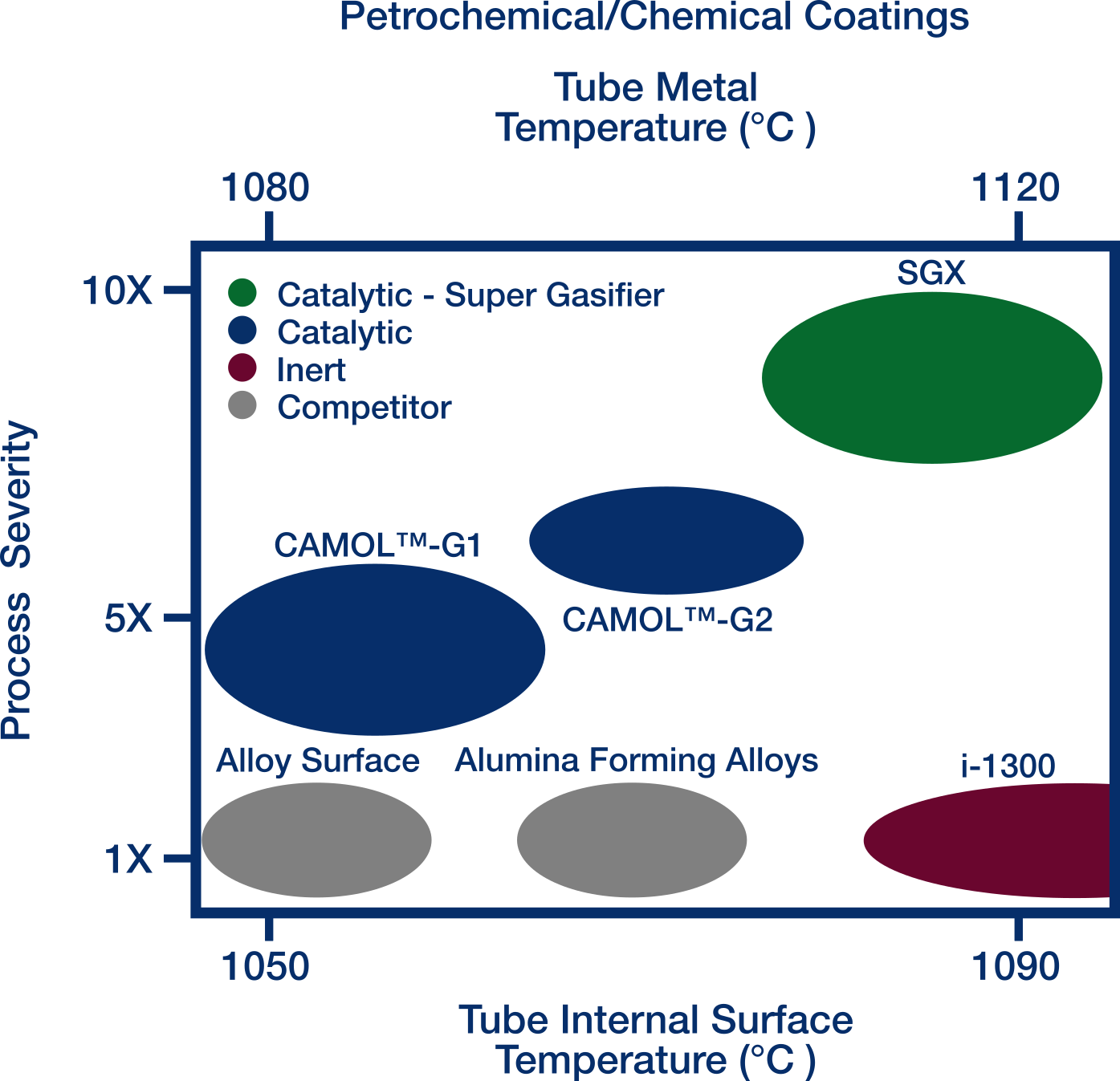

CAMOL™ is a patented composite metallic-ceramic coating for service in Medium Severity Cracking, which is deposited on the inner surface of the radiant tubes and fittings of a Petrochemical steam-cracking furnace coil for two main purposes:

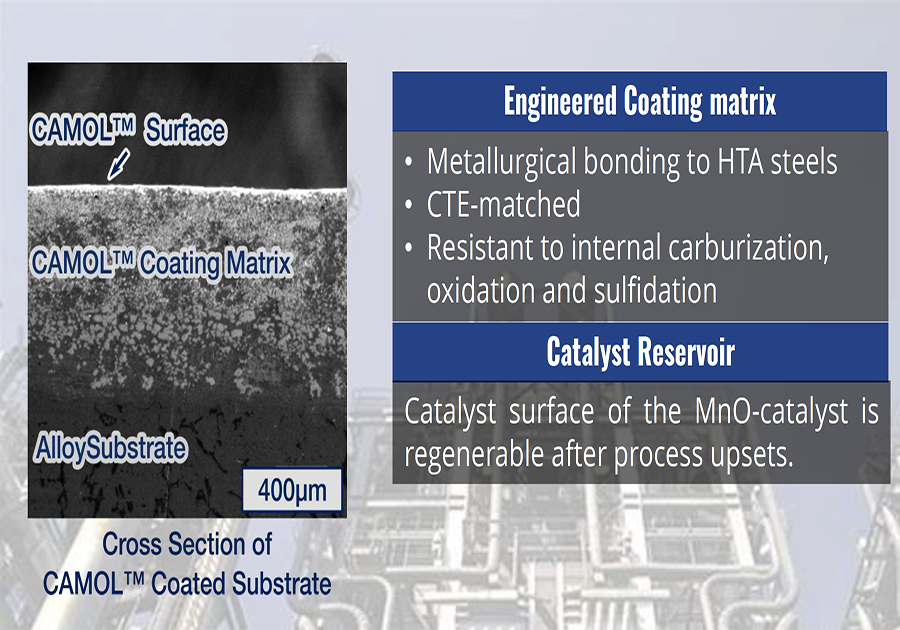

As a protective barrier - CAMOL™ protects the internal wall of the tubes by generating a coating matrix up to 500 microns thick that: (1) protects the base steel from degradation processes that include internal oxidation, carburization and sulfidation; and (2) enables the generation and regeneration of a surface oxide protective layer for functional coke gasification.

As a gasifying catalyst - CAMOL™ provides a catalytic surface that gasifies coke that forms in the gas-phase (amorphous coke) and which would otherwise collect on the internal tube wall into CO and/or CO₂, thus offering a two-pronged approach to address the two major sources of coke-make, catalytic (filamentous) and amorphous (gas-phase) coke. The surface oxide layer is inert to filamentous (catalytic) coke-make and is typically <10 microns in thickness and which can be regenerated / repaired through normal furnace operation.

Energy and Emissions

Longer Runtime

Coil Life

Increased Yields

CAMOL™ coated products are the first-ever coatings brought to market that provide their engineered properties for a full life cycle of 4-7 years when used within operating envelope of base steel and coating.

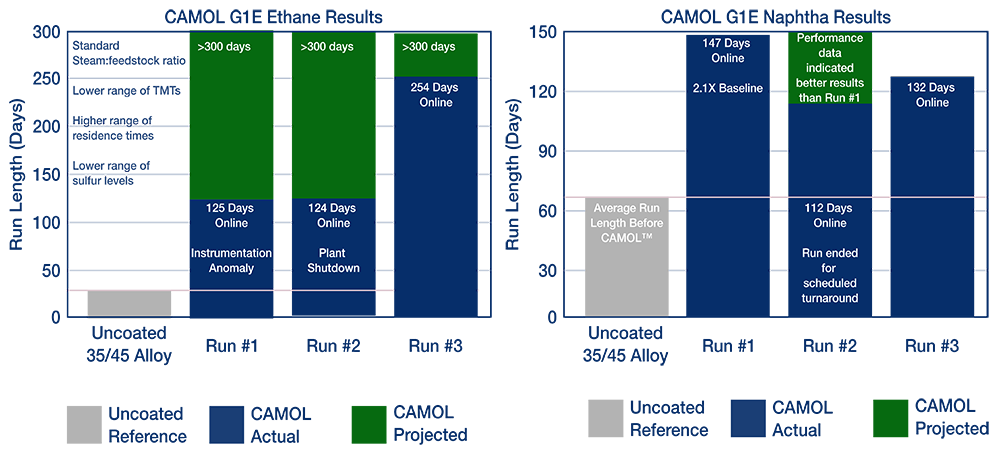

With 12 field trials undertaken in ethane and naphtha crackers of global petrochemical producers, when operating at Medium Severity Cracking, the technology has demonstrated:

Full-cycle field trials have been completed with run-lengths at the end-of-life being near-equivalent to those at start-of-life, and anti-coking benefits of at least 5 years, when operating within the Operating Envelope of both the base steel and the CAMOL™ coating.